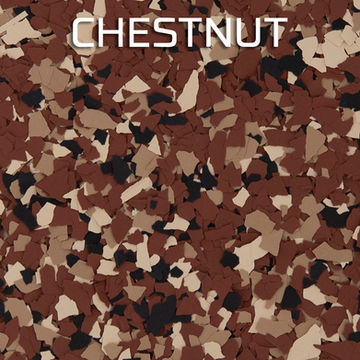

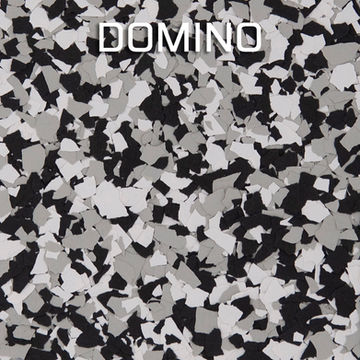

Colors Available

RESIDENTIAL

CONCRETE COATING

As dazzling as it is durable

Transform your patios, driveways, and walkways into outdoor havens that endure the rigors of time, from de-icers and chemicals to heavy foot traffic. CHP Concrete Coating offers the toughest industrial concrete coating available, elevating the aesthetics of any concrete floor. With installation completed in just one day and a speedy 24-hour return to service, you can swiftly relish the transformed space.

Our garage floor coatings come in customizable colors to complement your personal style and home decor. Beyond their aesthetic appeal, these coatings prioritize safety with slip-resistant features, particularly crucial in regions like Wyoming and Northern Colorado. We are so confident in our design and process, we offer a limited lifetime warranty.

THE PROCESS

1. Polyurea Base Coat

This foundational layer establishes the primary color for the flooring while creating a durable connection to the concrete, safeguarding against peeling even in the face of hot tires or significant temperature fluctuations. Before applying this coating, we meticulously grind the concrete floor to ensure optimal adhesion.

2. Decorative Flakes

The vinyl flakes are scattered across the base coat, seamlessly adhering to the floor and crafting a visually stunning mosaic guaranteed to captivate. Additionally, these chips impart a subtle texture, enhancing the floor's slip resistance for added safety.

3. Polyaspartic Top Coat

The ultimate layer serves as a shield, safeguarding your garage floor against typical wear and tear, including exposure to de-icers, chemicals, and debris lodged in tires. Moreover, it boasts UV resistance, ensuring it remains free from yellowing over time, maintaining a fresh appearance for years to come.

Why is it better than epoxy floors?

-

Fully curing within a single day, our Epoxy Flooring eliminates the inconvenience of a potential week-long cure time, sparing your vehicle from exposure to hail damage.

-

Its enhanced flexibility accommodates significant temperature variations, allowing for expansion and contraction without compromise.

-

Unlike epoxy, which requires temperatures above 40 degrees throughout the entire curing process to prevent failure, Polyurea can cure even in frigid conditions down to -20 degrees.

-

Additionally, our flooring is four times tougher than traditional epoxy floors, ensuring exceptional durability and longevity.

FLOORS

WAREHOUSES

WORKSPACES

BASEMENTS

PATIOS

SHOWROOMS

First off, the epoxy kits don't come with a 500 pound planetary concrete grinder hooked to commercial HEPA vacuums. This concrete grinder has 9 diamond heads that abrade the surface to ensure our product has permanent adhesion.

Second, the epoxy kits do not come with a patching compound that fills chipped, cracked and spalled concrete. Our concrete patching compound mends surface damage to a strength harder than the concrete.

Third, the epoxy kits come with a small baggy of the colored chips that are lightly sprinkled across the garage. Our chips come in 40 lb boxes that are cast over the entire floor until they are piled on top of each other. The excess chips get reclaimed and a gorgeous mosaic landscape is left. The color options are endless, so let your mind go wild! The density of the chips also creates a texture that hides minor imperfections and gives the floor slip resistance.

Forth, many epoxy kits do not come with a clear top coat. Our Polyaspartic clear top coat is the armor of the floor coating system. It gives the floor scratch, chemical and stain resistance. It is also non-porous, so it gives the floor an incredible shine that is easy to clean and anti-microbial.

Fifth, epoxy is not UV stable and yellows over time. Our Polyurea is UV stable, so it will not yellow over time and can be applied outside as well.

Sixth, the epoxy kits come with no real warranty or customer support. Once your hot tires park on the surface and peels the coating, you are stuck with an unsightly floor. Our product has a 15 year residential warranty from peeling and chipping. Commercial floors have a 5 year warranty.

It can be applied on about any concrete floor imaginable. It is very common to apply this coating in garages, shops, patios, walk ways, basements, laundry rooms, mud rooms, dog kennels, driveways, restaurant floors and other commercial floors.

Most garage floors can be completed in a single day. Once the top coat has been applied, all items can be moved back onto the floor 24 hrs. later.

Yes, our Polyurea can cure down to -20 degrees F. We are used to installing concrete coatings in many conditions in Cheyenne, Laramie, Greeley, Wellington, and the surrounding areas.

The texture of the flake gives the floor some slip resistance, but if more slip resistance is desired, varying levels of polymer sand can be added into the top coat.

It covers free spot repair for any peeling coating on a concrete surface that we were able to effectively grind. Our mender fills cracks, but cannot prevent cracks from continuing to grow or move. If cracks come through the coating after installation, it is because the concrete beneath is cracking. If this happens, we can come back to refill the crack, but it is not covered under our warranty and there may be a service charge. General use will dull the clear coat over the years. This is considered normal wear and tear. If a brand new shine is desired, we can apply another clear coat at an additional charge. Any damage due to excessive wear and tear not typical for the area would not be included. Any chipped areas will be evaluated on a case-by-case basis. If the concrete itself has been chipped in that area, then the warranty doesn't apply.